Element provides galvanic corrosion tests in accordance with ASTM G71 and client-specific standards for evaluating the behavior of metals and metallic coatings in accelerated corrosion environments. We help you select appropriate materials at the design stage and offer in-field support to give fast answers in live applications.

Galvanic corrosion occurs when two or more dissimilar metals (electrodes) are brought into electrical contact in the presence of a common corrosive electrolyte (e.g. seawater). When a galvanic couple forms, the less resistant material becomes the anode and the more resistant the cathode. The cathodic material corrodes slower than normal or not at all, while the corrosion of the anodic material is greatly enhanced.

Our leading corrosion testing laboratories carry out galvanic corrosion testing on combinations of metals and metallic coatings to evaluate the damage due to galvanic corrosion. We can assist you in selecting the right materials combinations for your required application.

Galvanic corrosion test standards and practices

- ASTM G82 - Guide for Development and Use of a Galvanic Series for Predicting Galvanic Corrosion Performance

- ASTM G71 - Practice for Conducting and Evaluating Galvanic Corrosion Tests in Electrolytes

Element’s Engaged Experts can apply the standard galvanic series of materials in seawater to predict service performance relatively to galvanic corrosion, whilst taking into consideration differences in environmental conditions that can greatly affect the rank ordering of materials.

Exposure of galvanic couples

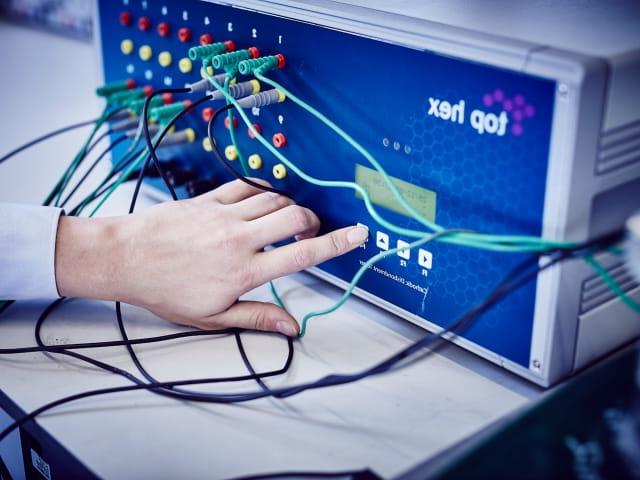

Our corrosion testing laboratories are able to simulate a material’s condition, environment and geometry as close to the application as possible. This allows us to simulate a galvanic corrosion situation where a galvanic couple is constructed between materials and placed in the environment of interest.

Electrochemical analysis

Element’s Engaged Experts perform electrochemical corrosion testing analysis to evaluate galvanic corrosion performance of two or more dissimilar metals when electrically connected in a selected environment using three main test categories:

- Sensitive galvanic current measurement using Zero Resistance Ammetry (ZRA)

- Galvanic series determination

- Preferential weld corrosion

The Element advantage

Our galvanic corrosion testing services provide you with the necessary data on how your materials and components are likely to perform when deployed in the field, to ensure they are always of a high quality and are safe, compliant and ultimately fit for purpose.

For more information about how we perform Galvanic Corrosion Testing, or to request a quote, contact us today.

Predicting component life with corrosion modeling

Erosion within oil and gas pipelines is a serious problem. Corrosion modeling using the Computational Fluid Dynamic method can accurately predict the location of burn-throughs.

Read MoreFAQ: What is Hydrogen Embrittlement?

Discover hydrogen embrittlement as Vikram Nanda, an expert in metallurgy and metallurgical failure analysis, provides answers to commonly asked questions in this article.

Read MOREIntergranular Corrosion Testing: An Overview of ASTM A262

ASTM A262 is a common intergranular corrosion testing method that can quickly screen batches of material to determine corrosion susceptibility. The ASTM A262 testing specification contains five unique intergranular corrosion tests.

LEARN MOREOther Energy Services

More from Element

Electrochemical Corrosion Testing

Element provides electrochemical corrosion testing using Electrochemical Impedance Spectroscopy, cyclic potentiodynamic polarization measurements and galvanic corrosion measurements.

Sour Service Corrosion Testing

Element is one of a few ISO certified sour service labs in the world, providing sour service corrosion services for a variety of test types including NACE MR0175/ISO 15156.

Resources

Discover blog posts, articles, white papers, webinars, and advice from our world-leading testing, inspection, and certification experts.

Element Locations

Learn more about our laboratories - where they are located; the unique capabilities they have and how they can help you solve your technical and commercial challenges.