Fatigue testing characterizes material or component behavior during cyclic loading. Our test machines can help test cyclic loads for vital properties, such as fatigue failure, fatigue limit, and fatigue life.

What is fatigue testing?

A fatigue test measures how cyclic forces will affect a product or material over time, by analyzing various sizes of cyclic loads in our test machines, under different speeds and environmental conditions, we can create predictive patterns for material behavior. While a large portion of fatigue tests are performed to plot stress (S) against the number of cycles to failure (N) (also known as an S-N curve), they can also be useful for simulating specific scenarios and investigating real-world fatigue failures.

Why is fatigue testing important?

Understanding fatigue properties is one of the most crucial elements of research and development, product safety, and material verification programs. It's important to test your materials & products to understand their performance, fatigue limit & fatigue life.

What is the purpose of fatigue testing?

Some products, such as medical devices, must conform to rigorous international standards for endurance properties. Other products, such as industrial components and consumer goods, often see manufacturers and testing companies working together to develop customized fatigue testing methodologies suited for the specific product’s application and end-use environment.

Material fatigue testing we offer

- Metals and alloys

- Composites

- Plastics and polymers

- Additively manufactured materials

- Fasteners

- Medical devices

- Pipes & tubing

- Steel Catenary Risers

- Welded samples & structures

- Industrial components, sub-assemblies, and equipment

- Gas turbine engines

- Engine airfoils

“Smooth communication, test quickly”

Aludyne

Types of fatigue testing we provide

- High cycle fatigue (HCF) testing

- Low cycle fatigue (LCF) testing

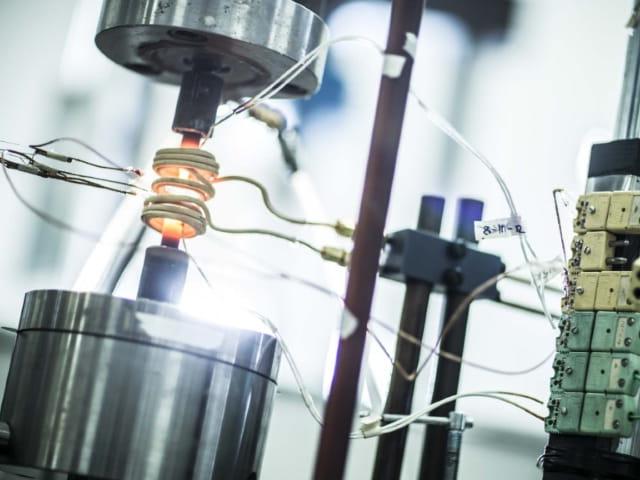

- Thermo mechanical fatigue (TMF) testing

- Axial fatigue testing

- Torsional fatigue testing

- Shear fatigue testing

- Proof load testing

- Bending fatigue testing

- Fatigue crack growth testing

- Resonance fatigue testing

- Multiple degrees of freedom fatigue testing

- Multi-channel/compound cyclic testing

- Strain Control

- Stress Control

- Displacement Control

- Frequency up to 100 Hz (rotating beam up to 150 Hz)

- Forces up to 250 kNTest temperatures from -320 to 2400 F)

- Custom and special project setups are available

ASTM fatigue testing standards we test for

- ASTM D3479

- ASTM D3039

- ASTM D6484

- ASTM D7615

- ASTM D5568

- ASTM 6115

- ASTM D7905

- ASTM E2368

- ASTM E466

- ASTM E606

The Element advantage

Element's laboratories around the world provide testing solutions to help make certain that your products and materials are safe and fit for purpose. Our analytical testing services utilize cyclic loads in test machines to understand fatigue failure under a multitude of different scenarios. We also apply constant amplitude and sinusoidal waveform applications during testing.

Understand when your product or material is at its fatigue life or fatigue limit with Element's test machines. Whether you require testing to existing standards or are interested in creating a custom test program, our experts are ready to assist with your materials testing needs.

For more information about our fatigue testing services or to request a quote, contact us today.

Fatigue & Fracture Toughness

Fatigue in metals caused by cyclic loading progressively damages a localized area of a structure, eventually leading to the formation of cracks. Once a crack is formed, it will grow with each application of load.

Learn more about fracture toughness in metals in our latest whitepaper and uncover how materials react under test conditions.

Free DownloadA Guide to Fatigue Testing in Composite Materials

We explain how composite fatigue testing is performed, key methods, how fatigue testing of impact-damaged laminates work, and fatigue crack growth testing.

READ MOREMultiaxial Fatigue Analysis

Multiaxial fatigue analysis replicates real-world service environments' load and stress conditions in controlled laboratory settings to develop safer materials and components.

Read moreFatigue Testing of Pipeline Girth Welds

Steel Catenary Risers are a critical element within many offshore pipeline installations. Learn more about the approach to the validation of the fatigue performance of pipeline girth welds in our whitepaper. READ MOREFatigue Failure: How can you Tell?

Fatigue failure is an extremely important design consideration for a variety of industries. Learn more about the characteristics of fatigue failure.

READ MOREFatigue Testing Methods

Element performs a variety of fatigue tests, including high cycle fatigue, low cycle fatigue, and specialized programs on a range of metals and alloys, polymers and components.

ASTM E606 Low Cycle Fatigue (LCF)

LCF testing is used for applications where materials are subject to extremely high mechanical stresses, and where plastic deformation is likely to occur.

ASTM E466 High Cycle Fatigue (HCF)

High cycle fatigue is used for materials that experience low applied forces and where deformation is primarily elastic in nature.

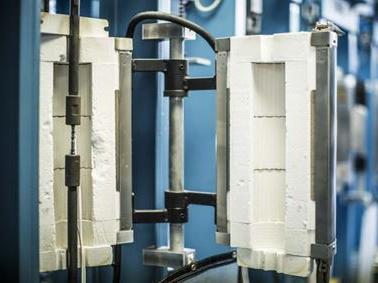

ASTM E2368 Thermo Mechanical Fatigue (TMF)

Element's ASTM E2368 thermo mechanical fatigue program provides testing services for a variety of materials qualification programs.

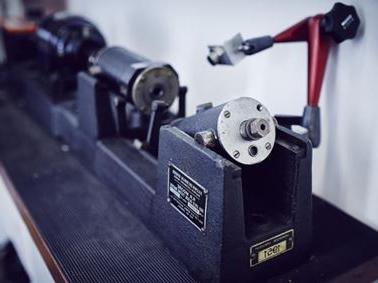

Rotating Beam Fatigue

Rotating beam fatigue is another testing method which is utilized to generate high cycle fatigue curves at a higher frequency than traditional HCF methods with single or multi-point bending stresses.

Stress Rupture Testing

Element offers stress rupture testing to understand the sudden and complete failure of a material under stress. Loads may be applied by tensile bending, flexural, biaxial or hydrostatic methods.

Creep Testing

Measuring load over an extended period of time, creep testing programs use continuous load and elevated temperature to test for eventual material failure.