问一个问题或要求报价

今天就和专家谈谈

PMMA骨水泥断裂韧性测试

骨水泥在膝关节置换术中固定关节, 臀部, 肩膀, 通过填充植入物和骨头之间的空隙来填充肘部. 在本文中, we discuss the methodology for measuring fracture toughness of polymethyl methacrylate (PMMA) bone cement.

PMMA is the most common form of bone cement and can come in several different varieties. 化学配方可以调整, 或者可以在水泥中浸渍抗生素, 哪些可以改变机械性能. The most important bone cement functions are to transfer the load from the implant to the bone and absorb shock between the two. 像这样, understanding the failure modes and the resistance to fracture is critical in evaluating performance.

骨水泥通常以两组分环氧树脂的形式提供, 由粉末和液体混合而成的. 在混合, the bone cement transforms from a runny liquid into a dough-like material that can be molded into the space. 在聚合过程中发生放热反应, 然后固化成硬化的水泥, 将植入物固定到位.

There are several test methods that can be used to evaluate the bone cement properties:

- ASTM F451 -丙烯酸骨水泥的标准规范

- ASTM F2118 - Test method for constant amplitude of force controlled fatigue testing of acrylic bone cements materials.

- ISO 5833 -外科植入物-丙烯酸树脂水泥

然而, this article will specifically outline plane-strain fracture toughness testing of PMMA bone cement using ASTM E399 and ASTM D5045 methodologies.

PMMA骨水泥断裂韧性评价

The purpose of ASTM E399 and ASTM D5045 standards is to determine the fracture toughness (K1C) of metallic or plastic materials. 断裂韧性试验 主要是在线弹性、平面应变条件下进行的. The typical specimen geometries used are compact tension (CT) and single edge notch bending (SENB).

在这里描述的示例中, 应用该方程对医用级PMMA骨水泥进行了测试, 在ASTM E399和ASTM D5045中描述的试样设计和试验方法. 我们使用SENB标本几何形状,并报告了K1C值.

样本设计

Selecting the proper specimen size and geometry is important to ensure plane-strain conditions at the crack tip are met. A sharp starter notch is needed to ensure a valid fracture toughness value is obtained.

选择合适的试样几何形状时, 考虑了几个因素, 包括可用材料的数量, 材料成本, 裂纹的方向和制作试样的难度. 由于大多数骨水泥的使用数量较小,且几何形状不同, trying to standardize a specimen is difficult as the common sizes have limited physiological relevance. The bone cement test specimen is created by mixing the liquid and powder at the appropriate ratios using the manufacturer’s recommended technique and pouring into a custom mold made to replicate the SENB geometry. This geometry uses less material and makes it easier to machine the material down to the final specimen size.

标本制作

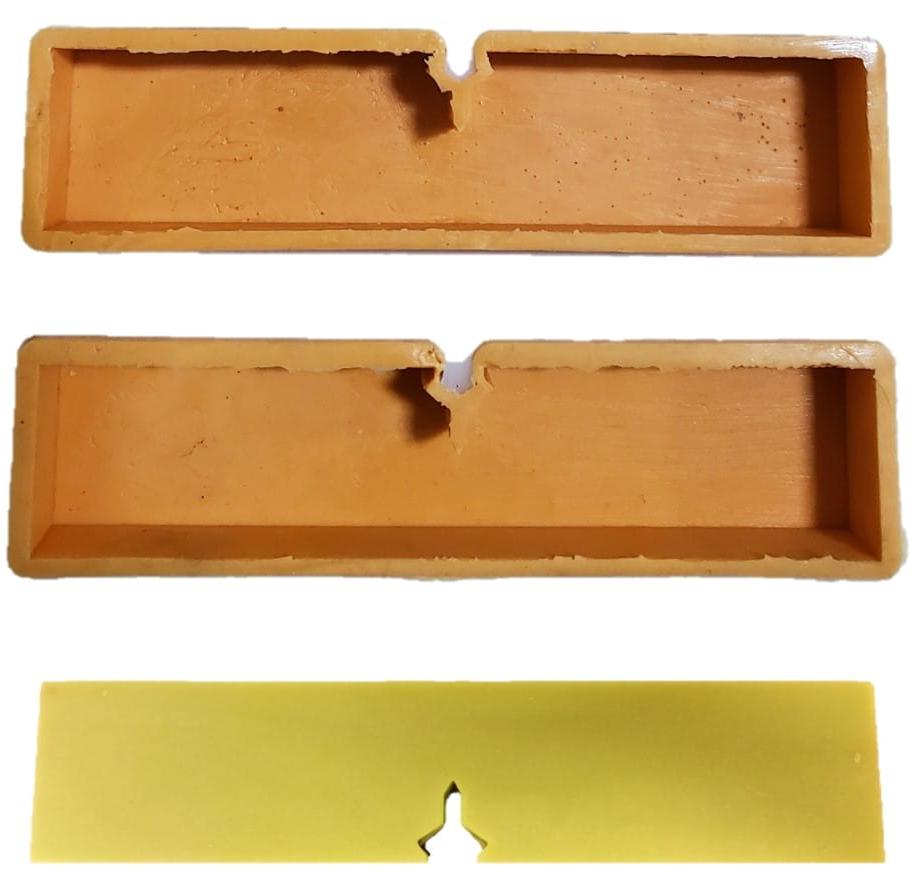

The custom mold used for creating a specimen is fabricated with food-grade silicone and Delrin material to provide sufficient stiffness (Figure 1). The mold is slightly over-sized and includes integral knife edges to allow for machining once the test specimen has formed and cured. This allows the removal of irregular surfaces and any distortion that occurred while the cement cured. 采取额外的步骤来清洁和准备测试的标本.

试验方法ASTM E399和ASTM D5045

The primary focus of this test is to subject the PMMA bone cement to plane-strain conditions. 测试平面应变条件, 一个锋利的缺口被用来在试样的期望位置产生裂纹. 疲劳载荷可产生裂纹, typically referred to as a fatigue pre-crack (ASTM E399) or a razor blade pressed into the specimen, 产生尖锐的缺口和裂纹(ASTM D5045).

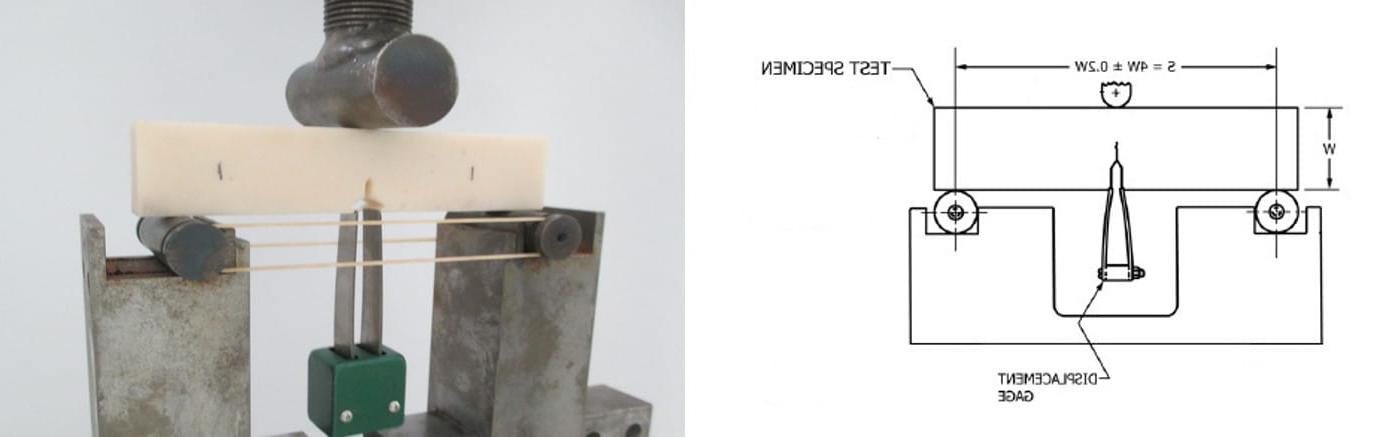

如果水泥具有脆性,则疲劳预裂效果最好. 将SENB试样加载到三点弯曲夹具中(图2), 在ASTM E399规范中概述, 产生疲劳预裂纹,进行断裂韧性试验.

如果水泥表现出延性, 首选的方法是ASTM D5045规范中描述的方法. This method calls for a razor blade to be pressed into the notch to create a crack similar to the fatigue pre-crack method. 至关重要的是,缺口是直的,延伸不小于0.050” into the specimen when using either the fatigue pre-crack or razor blade method. After a crack has formed penetrating dyes assist in differentiating the crack and the fracture toughness test on the specimen’s fracture surface.

断裂韧性试验采用与疲劳预裂纹法相同的夹具. 用于PMMA骨水泥, the loading rate called out in ASTM E399 is too fast and will cause inconsistent results. A modified displacement rate described in ASTM D5045 is suitable for the material and provided more consistent results. 建议对每种材料条件进行三次或更多的测试.

After specimens are loaded, a load versus loading point displacement curve is generated. 数据输出通过确定K1C值的多次计算路由.

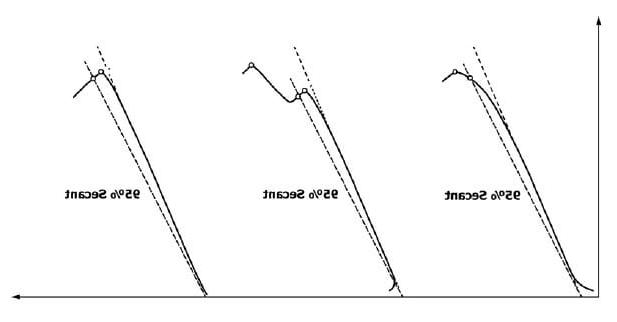

ASTM E399和D5045脆性材料的报告和分析

ASTM E399和D5045是脆性材料的理想测试方法. Three force-displacement modes exist (Figure 3) with a 95% deviation (or secant) from the initial linear portion. 在这张图上, the point where the 95% deviation crosses the test data is important for determining test validity (it qualifies as a K1C – qualifying that the specimen size was sufficient to plane-strain conditions). As the difference between this 95% deviation intersection and the maximum force increases, 测试无效的可能性就越大. 如果差异太大,ASTM E399允许使用替代测试方法.

影响测试有效性的其他因素是预裂纹长度, pre-crack平直度, 加载速率. If any of these are invalid, then the final fracture toughness value must be reported as invalid. 然而,无效的断裂韧性值并不意味着数据不可用. The invalid value can be used in the same applications as a valid fracture toughness value, but if a valid fracture toughness value is needed then additional testing is needed to investigate the factors that caused the invalidity. Making changes to testing parameters or specimen size will not guarantee a valid fracture toughness value.

The overall test output (K1C) measures the materials ability to resist fracture in the presence of a flaw which is crucial for understanding the properties of bone cement.

im体育APP优势

我们的专职专家擅长 医疗器械测试 and have worked with many challenging device designs and test setups over the last several decades. im体育APP 讨论我们如何帮助你的测试项目.

im体育APP拥有世界上最广泛的医疗设备测试范围之一, ranging from orthopedics and cardiovascular implants testing to EMC/EMI/product safety testing, 以及生物和包装评估. 我们努力以最方便的方式满足您的所有医疗器械测试需求, 高效反应方式.

找到相关的 资源

获取白皮书、最新动态和活动邀请

订阅内容更新

相关服务

医疗器械试验规程

一个协议和计划会降低你的风险, 防止混淆, 设定明确的期望, 并保留必要的信息以备将来参考和使用.

防止矫形器材的微动腐蚀

The human body is a corrosive environment that can compromise the performance of orthopedic devices. The test methods outlined in this article aid in preventing fretting corrosion in your device designs.

股骨膝关节构件的疲劳试验

Fatigue testing of femoral knee components is an important step in the validation process to ensure patient safety and device longevity. 向我们的专职专家学习.