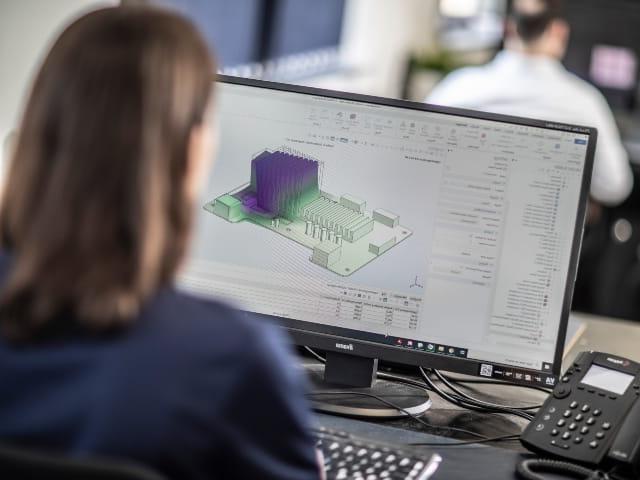

Element先进的有限元分析(FEA)和建模服务支持产品开发, simulation of service conditions, design optimization, life prediction, fitness for service, and failure analysis. 我们的专家与传统的测试服务合作,分析复杂结构和系统的强度, determine component behavior, 准确预测产品在结构和热负荷下的反应.

What is finite element analysis (FEA)?

有限元分析使用一系列数学模型来模拟一个零件或一组零件在预先定义的一组条件下的反应或行为.

What are the types of FEA analysis?

有限元法可用于求解工程连续介质力学的任何方程, including fluid flow, acoustics, and electromagnetics, 但最常用于求解应力和应变方程. We use static FEA to solve for strength and integrity, and dynamic FEA to solve for impact, explosions, and penetration.

What are the advantages of FEA?

有限元分析自20世纪60年代以来一直在使用,是一种精确计算结构在荷载作用下的应变应力的行之有效的方法. 现代计算能力现在允许我们考虑复杂的设计和材料组合在巨大的不同负载条件下. Multiple failure scenarios can now be examined safely and quickly, without the expense of full-scale test apparatus.

Applications of FEA

We use FEA for a wide range of different applications:

- 我们用它来计算航空航天中高载荷部件的应力, nuclear, defence, medical, chemical and offshore industries to identify the risks of failure.

- 扩展的有限元分析方法可以用来明确地模拟裂纹的扩展,以预测失效时间.

- 本文采用动态有限元分析方法研究了燃气轮机叶片失效及叶片是否会穿透发动机周围的保护机匣等情况.

- By coupling with acoustic or flow solvers, 我们可以计算化学过程系统中由高频振动引起的应力, and hence their fatigue lives.

- 我们使用相同的基本方法来计算海底设备的表面电势,以优化被动或主动阴极保护系统的设计.

Elements FEA analysis services

我们的专家在各行各业广泛工作,帮助您了解产品的结构和热性能. Our wide range of FEA services include:

- Linear static and dynamic stress analysis

- 非线性分析包括材料非线性、大变形和接触

- FEA modal analysis

- Structural optimization

- Time-dependent analysis (creep, stress relaxation)

- 裂纹扩展模型(j积分、内聚区、虚拟裂纹闭合技术)

- Fatigue life and durability analysis

- Residual life evaluation

- Engineering critical assessment (ECA) and fitness for service (FFS)

- Damage tolerance of composite materials

- 动力分析,包括频率、振动和随机振动

- Impact and high rate deformation

- Heat transfer analysis

- Thermal analysis

- Electromagnetic analysis

- Fluid diffusion/permeation

- FEA analysis report

Solving problems with FEA

我们用这种方法来求解结构力学问题和评估服役适应度, fatigue life, failure analysis, or perform design optimization. In addition, 我们也用它来解决涉及传热的其他工程和物理科学领域的问题, fluid flow, mass transport, and electromagnetism.

用我们先进的模拟软件来预测产品的行为, 我们可以帮助您节省传统测试所需的时间和材料,并增加您对测试合规性的信心.

FEA for Failure Analysis

我们的有限元分析专家通过CAD的调查定期解决产品故障问题, in-service data, and material data coupled with detailed analysis. 我们的FEA团队与物理测试专家密切合作,为您的测试失败提出解决方案,并通过物理测试验证模拟.

The Element advantage

Element在执行有限元分析(FEA)测试和为不同im体育平台app下载提供先进解决方案方面拥有超过30年的经验, including nuclear, aerospace, power generation, energy, defence, medical equipment and chemical process.

With state-of-the-art product testing facilities in the UK, we provide environmental simulation, durability cycling, structural dynamics programs, and mechanical testing in the same program. 这使我们成为您资质测试需求的单一来源提供商.

Digital Twin White Paper - Predicting Performance and Integrity

The concept of the digital twin 可以被认为是物理产品、工程系统或设施的虚拟表示吗. This paper presents the role of predictive engineering analytics, alongside operating data, in the digital twin. DOWNLOAD NOW利用有限元分析(FEA)识别复合材料的分层

分层是测试复合材料时要考虑的一个重要因素, particularly when comparing this to metallic materials. 复合材料的分层可能是由高层间应力和低通过厚度强度引起的,这使得复合材料具有更大的失效风险. READ MORE流动诱发振动加速管道系统疲劳失效

Flow Induced Vibration (FIV), 脉动与声激振动(AIV)的相关问题, 是否由管道系统的流量和压力波动引起,如果不正确识别和减轻,可能导致加速疲劳失效. READ MORERelated Pages

Computational Fluid Dynamics (CFD)

我们使用计算流体动力学(CFD)来模拟和分析涉及流体-流体的复杂问题, fluid-solid, and fluid-gas interactions.

Modeling and Simulation

我们专注于建模和仿真,以加速您的研究和开发计划, optimize your designs and support safe, efficient operations.

Data Science and Machine Learning

我们将最先进的数据科学和机器学习相结合,提供见解,帮助您提高绩效和生产力.