im体育APP supports the 能源 Industry in managing the challenges of polymeric materials like elastomers, 热塑性塑料, 热固性材料, and composites in service in supercritical CO2 environments.

作为 发电 im体育平台app下载, Carbon Capture Utilisation and Storage (CCUS) requires the containment and transport of supercritical CO2 (scCO2) in large quantities through pipes, 阀门, 压缩机, 等, each of which can contain non-metallic components essential for safe and efficient operation. These components can be items such as liners, 密封件和垫片, or even composite structural parts and valve bodies.

scCO2 properties and non-metallic materials

由于它的特点, scCO2被用作无毒的, 可回收的, low-energy solvent in many other industries, 包括粮食生产, 药品, 以及建筑材料. 高于31°C和73°C.8 bar, CO2 turns to superritical CO2, showing characteristics of a liquid and a 气体. It can permeate as quickly as a 气体 and be absorbed as much as a liquid. This presents the worst of both worlds in performance terms. 这种现象导致

- high permeation rates (influencing metal corrosion rates, 污染, 污染, 以及产品耐久性的损失),

- rapid 气体 decompression problems (including blistering, leaching out of stabilizers and plasticizers in the polymer)

- and excessive swelling leading to tearing of the material.

Non-metallic components like thermoplastic pipes and elastomeric O-rings are susceptible to swelling in contact with scCO2; the level of swell varies with temperature and pressure. In addition, elastomers are prone to 快速气体减压(RGD) 损害. The latter occurs when external pressure is released quickly, and the pressurized CO2 present in the polymer is unable to leave naturally by diffusion. At standard pressure and temperature, the volume of CO2 absorbed by a small seal can be significant, 很容易达到100立方厘米, which means it can suffer irreversible fracture 损害 and possibly mechanical 损害, such as local extrusion in service due to significant swell.

scCO2暴露试验

到 石油 & 天然气工业 supercritical CO2 has been present as a constituent of hydrocarbon production and for injection for decades. Our experts have significant experience and knowledge of how these materials behave in scCO2; this includes performance aspects such as dimensional stability, 耐化学老化, RGD的阻力, 和磁导率. Exposure tests to 1000 bar and 200 °C are routine, as are multi-cycle RGD/blister resistance tests and long-term (>1 year) durability tests.

im体育APP优势

im体育APP has supported the wider energy industry as it manages the challenges scCO2 presents to non-metallic materials for over 30 years. We have developed novel assessment and inspection techniques specifically to address the potential issues around scCO2 and polymers, allowing us to create and run customized test programs for our customers.

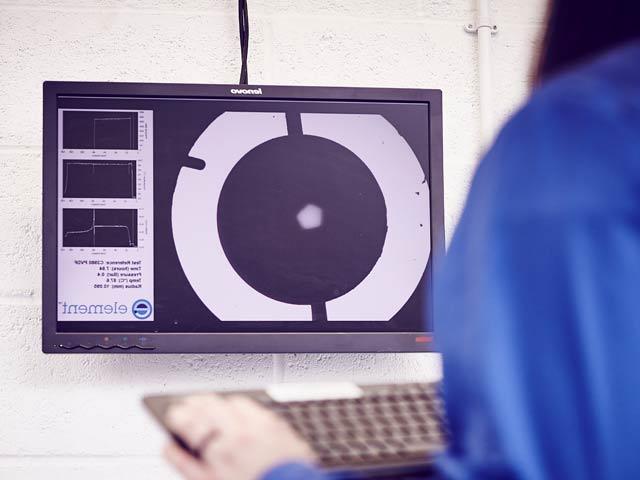

As im体育APP’s Global Center of Technical Excellence for Polymers, the materials testing laboratory in 哈特金 has designed a unique visual observation fixture that allows to monitor and measure materials in-situ whilst under pressurized scCO2 conditions. This includes the effect of pressure/temperature changes assessed in-situ, 以及RGD的作用.

For more information about testing the effects of scCO2 on non-metalics or to request a quote, im体育APP 今天.

Whitepaper: Rapid Gas Decompression (RGD) Tests Involving 氢 Sulfide

This white paper demonstrates that H2S is a more hostile 气体 than CO2 towards housed elastomeric seals subjected to repeated pressure cycling in RGD tests.

im体育官方app下载Understanding 氢 Permeation 测试 on Non-Metallic Materials

氢 permeation testing can provide manufacturers with important knowledge such as how much hydrogen is going to pass through a material.

im体育官方app下载Understanding Mixed Flowing Gas 测试

Mixed flowing 气体 (MFG) testing is an accelerated aging test that specifically evaluates the corrosion of electrical components due to exposure to atmospheric 气体ses and contaminants.

im体育官方app下载更多能源测试服务

Rapid Gas Decompression 测试 (RGD)

im体育APP offers rapid 气体 decompression testing to help manufacturers and users of elastomers better understand the behavior of this material in true sour RGD conditions.

碳捕集与封存

Learn more about our testing capabilities to prevent corrosion at transport infrastructure for 碳捕集与封存 (CCS).

氢

im体育APP has decades of experience in testing materials and components for their behavior in hydrogen-containing environments.

涂料测试

Find out about im体育APPs range of coatings testing services designed to help to make certain that materials, products and pipelines we test for our customers are protected from corrosion, 紫外线, 渗水, 热, 磨损和化学品.