Highly Accelerated Life Testing (HALT testing) and Highly Accelerated Stress Screening (HASS testing) provide efficient and reliable methods for combining multiple test types into a single, comprehensive testing program.

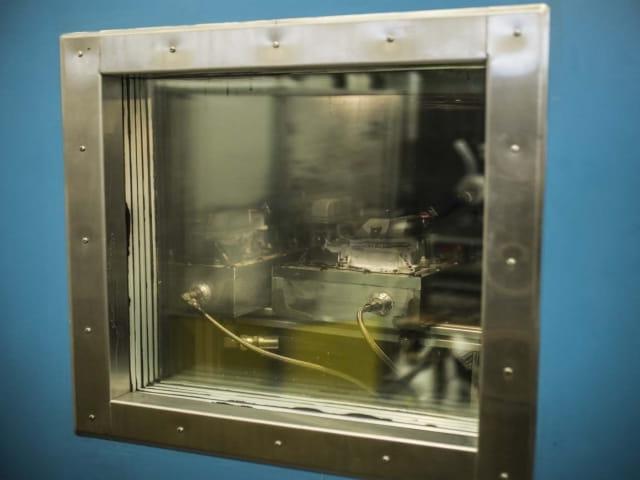

Element’s HALT testing and HASS testing capabilities combine high temperatures with random vibration to evaluate the performance and durability of a design and product reliability. HALT testing is frequently used in R&D and product design validation to anticipate issues before they arise, and avoid costly mistakes that might occur in full-scale testing, or in the field.

HALT testing provides essential information about the performance of finished components, systems, and sub-components. Element's engineers simulate real-world environmental testing and climatic test conditions to uncover hidden defects before sending the product to market, which prevents the product development life-cycle costs. By monitoring system performance throughout the testing process, Element can provide crucial details about the structural vulnerability, thermal reactions, useful life, and more.

The Element advantage

Element’s HALT and HASS testing capabilities are designed to support a variety of high-quality test programs, while controlling cost and reducing time-to-market. Our engineers work with you to design and execute a testing protocol that provides accurate and reliable results, while helping you stay on budget and meet your contractual requirements.

For more information about our HALT testing and HASS testing programs, or to speak to an expert, contact us today.

Related Services

Climatics and Environmental Simulation

Element can provide you with critically important data on your product or part's performance in response to typical or extreme environmental conditions.

Product Testing

From environmental & dynamic testing to highly specialized tests such as bird strike and hydrodynamic ditching testing, we're the trusted testing partner to the world's most recognized component and system manufacturers.

Vibration Testing

Find out how Element's vibration testing services help to make certain that the products we test for our customers will perform safely and as expected when in the field.

Product Testing Laboratories

Element's product qualification testing labs span the US, UK and Germany, providing testing services to clients in Aerospace, Transportation, Oil and Gas and more.