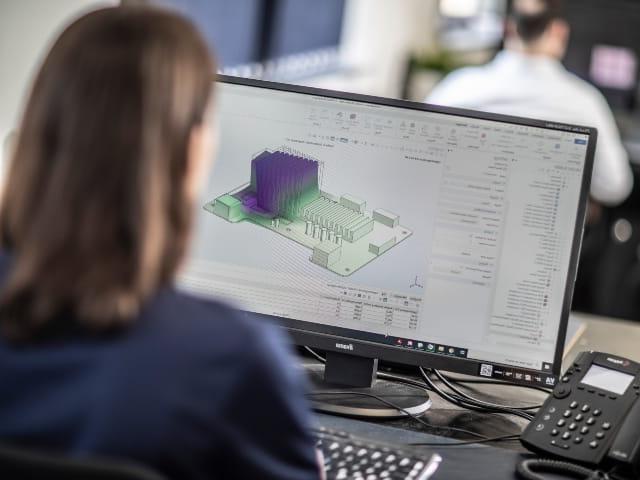

Element’s advanced Finite Element Analysis (FEA) and modeling services support product development, simulation of service conditions, design optimization, life prediction, fitness for service, and failure analysis. Our experts work with traditional testing services to analyze the strength of complex structures and systems, determine component behavior, and accurately predict how products will react under structural and thermal load.

What is finite element analysis (FEA)?

FEA uses a series of mathematical models to simulate the response or behaviour a part or set of parts will have under a previously defined set of conditions.

What are the types of FEA analysis?

The Finite Element Method can be used to solve any of the equations of engineering continuum mechanics, including fluid flow, acoustics, and electromagnetics, but is most commonly used to solve the equations of stress and strain. We use static FEA to solve for strength and integrity, and dynamic FEA to solve for impact, explosions, and penetration.

What are the advantages of FEA?

Finite Element Analysis has been in use since the 1960s and is a well-established way of accurately calculating the stresses in strains in structures under load. Modern computational power now allows us to consider complex designs and combinations of materials under a huge range of different load conditions. Multiple failure scenarios can now be examined safely and quickly, without the expense of full-scale test apparatus.

Applications of FEA

We use FEA for a wide range of different applications:

- We use it to calculate the stresses in highly-loaded components in the aerospace, nuclear, defence, medical, chemical and offshore industries to identify the risks of failure.

- Extended FEA methods can then be used to explicitly model the growth of cracks to predict the time to failure.

- We use dynamic FEA to study situations such as the failure of a gas turbine blade and whether it will penetrate the protective casing around the engine.

- By coupling with acoustic or flow solvers, we can calculate the stresses caused by high-frequency vibrations in chemical process systems, and hence their fatigue lives.

- We use the same fundamental method to calculate the surface electropotential ofsubsea equipment to optimise the design of passive or active cathodic protection systems.

Elements FEA analysis services

Our experts work extensively across all industries to help you understand both the structural and thermal performance of your products. Our wide range of FEA services include:

- Linear static and dynamic stress analysis

- Non-linear analysis including material non-linearity, large deformation and contact

- FEA modal analysis

- Structural optimization

- Time-dependent analysis (creep, stress relaxation)

- Crack growth modeling (J-integral, cohesive zone, virtual crack closure technique)

- Fatigue life and durability analysis

- Residual life evaluation

- Engineering critical assessment (ECA) and fitness for service (FFS)

- Damage tolerance of composite materials

- Dynamic analysis, including frequency, vibration and random vibration

- Impact and high rate deformation

- Heat transfer analysis

- Thermal analysis

- Electromagnetic analysis

- Fluid diffusion/permeation

- FEA analysis report

Solving problems with FEA

We use this method to solve structural mechanics problems and evaluate fitness for service, fatigue life, failure analysis, or perform design optimization. In addition, we also use it to solve problems in other fields of engineering and physical sciences involving heat transfer, fluid flow, mass transport, and electromagnetism.

With our sophisticated simulation software that predicts product behavior, we can help you save time and material required for traditional testing and increase your confidence in test compliance.

FEA for Failure Analysis

Our finite element analysis experts regularly solve product failure issues through the investigation of CAD, in-service data, and material data coupled with detailed analysis. Our FEA teams work closely with physical testing experts to suggest solutions to your test failures and to validate simulation with physical testing.

The Element advantage

Element has over 30 years of experience in performing Finite Element Analysis (FEA) testing and delivering advanced solutions to diverse industry sectors, including nuclear, aerospace, power generation, energy, defence, medical equipment and chemical process.

With state-of-the-art product testing facilities in the UK, we provide environmental simulation, durability cycling, structural dynamics programs, and mechanical testing in the same program. This makes us a single-source provider for your qualification testing needs.

Improving Emissions Performance Within Waste-to-heat Process System

A developer of a novel compact waste-to-heat process system needed help with minimizing the thermal stresses induced in the structure by the high-temperature pyrolysis processes used to treat the waste. The customer also wanted to maximize the environmental emission performance. READ MOREDigital Twin White Paper - Predicting Performance and Integrity

The concept of the digital twin can be thought of as a virtual representation of a physical product, engineering system or facility. This paper presents the role of predictive engineering analytics, alongside operating data, in the digital twin. DOWNLOAD NOWUsing Finite Element Analysis (FEA) to Identify Delamination of Composites Materials

Delamination is an important factor to consider when testing composites, particularly when comparing this to metallic materials. The delamination of composite materials can be caused by high interlaminar stresses in conjunction with low through-thickness strength which puts composite materials at greater risk of failure. READ MOREFlow Induced Vibration Accelerating Fatigue Failure in Piping Systems

Flow Induced Vibration (FIV), and the related problems of pulsation and Acoustic Induced Vibration (AIV), are induced by flow and pressure fluctuations in piping systems and can lead to accelerated fatigue failure if not properly identified and mitigated. READ MORERelated Pages

Computational Fluid Dynamics (CFD)

We use Computational Fluid Dynamics (CFD) to simulate and analyze complex problems involving fluid-fluid, fluid-solid, and fluid-gas interactions.

Discrete Element Method (DEM)

Our Discrete Element Method (DEM) services deliver innovative solutions that have helped companies across a wide range of industries.

Modeling and Simulation

We specialize in modeling and simulation to accelerate your research and development initiatives, optimize your designs and support safe, efficient operations.

Data Science and Machine Learning

We combine state-of-the-art data science and machine learning to provide insights that help you improve performance and increase productivity.