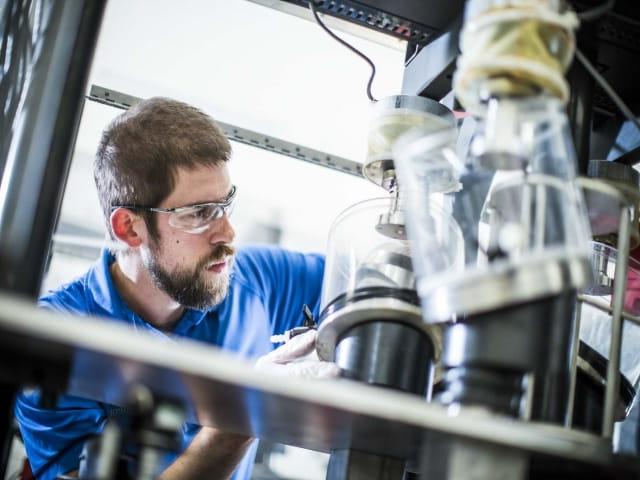

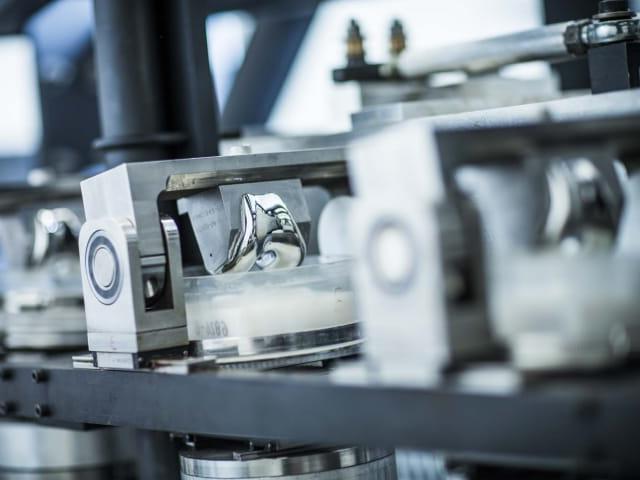

Medical device wear testing is used to characterize the tribological properties of implants and prosthetics by simulating the kinematics and kinetics of the human body, in an environment that closely simulates intended use.

To ensure accurate results for extended use, medical device wear testing programs are generally long-term programs. Testing is typically run at 1Hz up to 5,000,000 cycles, with mass loss evaluations conducted throughout testing and a particle characterization performed post-test. Depending on the project requirements, a medical device wear test can last anywhere from 4-6 months.

The Element Advantage

Because of the lengthy nature of medical device wear testing, it’s critical to partner with a lab that has experience with a regulatory body and understands the requirements regarding test methodology and reported data. Element manages every aspect of your medical device wear test program in-house, including testing and surface evaluation, mass loss measurements, and final reporting. By partnering with Element, you can take confidence in our diligent oversight and testing accuracy, and our ability to repeat your testing program.

For more information about our medical device wear test capabilities, or to speak with an expert, contact us today.

Ready to request a quote?

Our deliverable is certainty - high quality data, test reports and certificates that you can absolutely rely on when making decisions about your materials and compliance. Engage with an expert today.

Other Product Qualification Testing Services

More from Element

Materials Characterization

Find out how Element helps its customers to characterize, evaluate, select and apply metals, polymers, rubbers and elastomers in their end products and applications.

Medical Device Testing

As a comprehensive testing partner, you’ll enjoy the benefit of a single supplier source for all of your testing needs, from mechanical testing and environmental simulation to EMC and wireless device testing.

Resources

Discover blog posts, articles, white papers, webinars, and advice from our world-leading testing, inspection, and certification experts.

Medical Device Testing Experts

Our Engaged Experts are experienced in every stage of medical device testing - from test protocol development and prototype/feasibility trials to testing for 510(k), CE, and other regulatory submissions