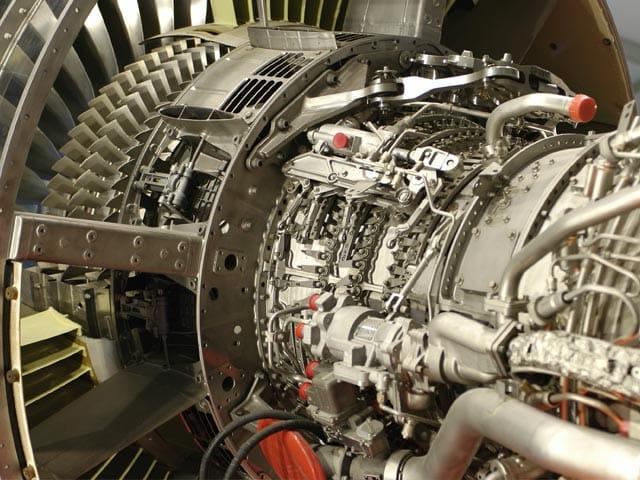

In an industry where failure is not an option, im体育APP can help to ensure that aircraft engines meet all safety standards and testing requirements. Our powerful equipment gives us the ability to reproduce the extreme vibration conditions of an aircraft engine facing a catastrophic failure, 如风扇叶片脱落事件.

航空发动机测试

Assure passenger safety with Nadcap accredited testing

Fan blade out events occurs when a foreign object (normally a bird) is ingested by an aircraft’s engine, 导致旋翼叶片脱落. The result is windmilling vibration, which often causes enough damage to halt power production, although the engine will continue to rotate due to the incoming airflow. This phenomenon is known as sustained engine imbalance, 或“风车旋转,’ and places a significant strain on an aircraft’s flight systems.

风milling testing ensures that these systems can handle the stress and remain operational. While these extreme conditions are difficult to replicate in standard testing, our LDS V8 electrodynamic test system can simulate even extreme events, providing the certainty you need to demonstrate your product’s compliance to any standard.

im体育APP优势

除了风车, im体育APP has the largest capacity for aerospace EMC and environmental testing in the UK, testing over a thousand aerospace products each year across six locations. We work with you to provide support through all stages of product qualification testing, helping to ensure that you can deliver against airframe manufacturers’ imposed qualification milestones. We can help you mitigate the risk of failing to meet critical deadlines such as safety of flight, and of receiving punitive measures for late delivery.

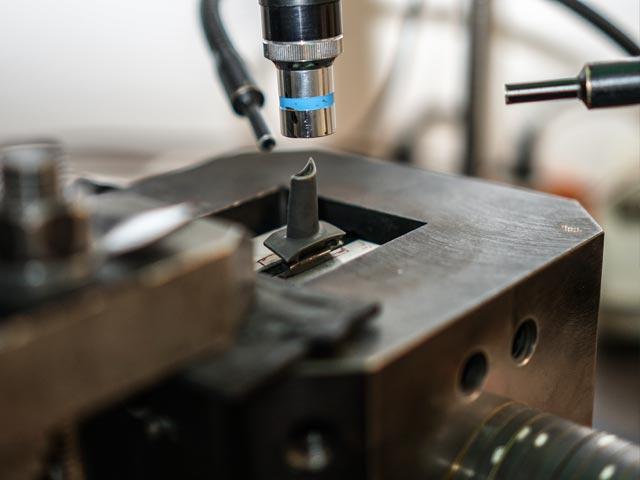

UKAS accredited to BS EN ISO/IEC 17025:2005, we deliver a unique range of wider testing and validation often required by aerospace manufacturers during qualification, 包括:

- Direct and Indirect Lightning 测试

- High Intensity Radiated Field (HIRF) 测试

- 高度测试与模拟

- 工程模拟 & 有限元分析

- 爆炸性环境试验

Our reliable results and timely approach have made im体育APP the preferred testing partner for many of the world’s leading aerospace manufacturers. Whether you are performing routine testing or looking to develop and take your products to market, we can help make your project a success.

相关服务

燃料系统

Find out how im体育APP's comprehensive fuel system testing programs simulate in-service conditions at our world-class testing facilities.

航空航天电磁干扰测试

State-of-the-art ISO/IEC 17025:2005 accredited laboratories enable us to test a wide range of products from the smallest components to the largest electrical power management systems for commercial and military aircraft.

航空航天材料测试

As the largest independent materials testing provider in the global 航空航天 sector, im体育APP is well-positioned to meet your every requirement, 从早期R&D开发项目, materials testing for production through to solutions for in-service challenges.

液压 & 气动

Find out how im体育APP tests hydraulic and pneumatic based fluid power systems for the global 航空航天 sector.